Enrobing machine PO 600.3

The machine is used for coating of confectionery products with various icings (cocoa, yogurt, white fat etc.) The machine is capable of making full, partial or bottom coating.

Upon customer’s request, the additional SK equipment can be attached to the enrobing machine that provides for additional topping of the enrobed products with coconut, ground nuts etc.

This new-generation equipment includes primarily the following elements:

- Complete stainless-steel design according to highest EU standards;

- The icing is conveyed by the originally designed pump;

- The construction allows very easy access to the hopper with the icing substance with optimized shape for easy cleaning and duplicator heating all over the surface;

- Removable and tilting feeding conveyer;

- Drawing-out enrobing conveyer on its own transporting frame allowing easy washing apart from the machine and turning of the belt;

- Easy shaking off the icing remnants with vibration belt;

- Automatic control by Mitsubishi micro-computer control unit;

- Continuous regulation of pump output and belt speed controlled by frequency converters.

Parametres

-

Length 1500 mm

-

Width 1150 mm

-

Height 1840 mm

-

Belt width 600 mm

-

Maximum product height 100 mm

-

Belt speed 0,6 - 1.8 m/min

-

Capacity of icing hopper ~ 50 l

-

Input 10,5 kVA

-

Total weight 650 kg

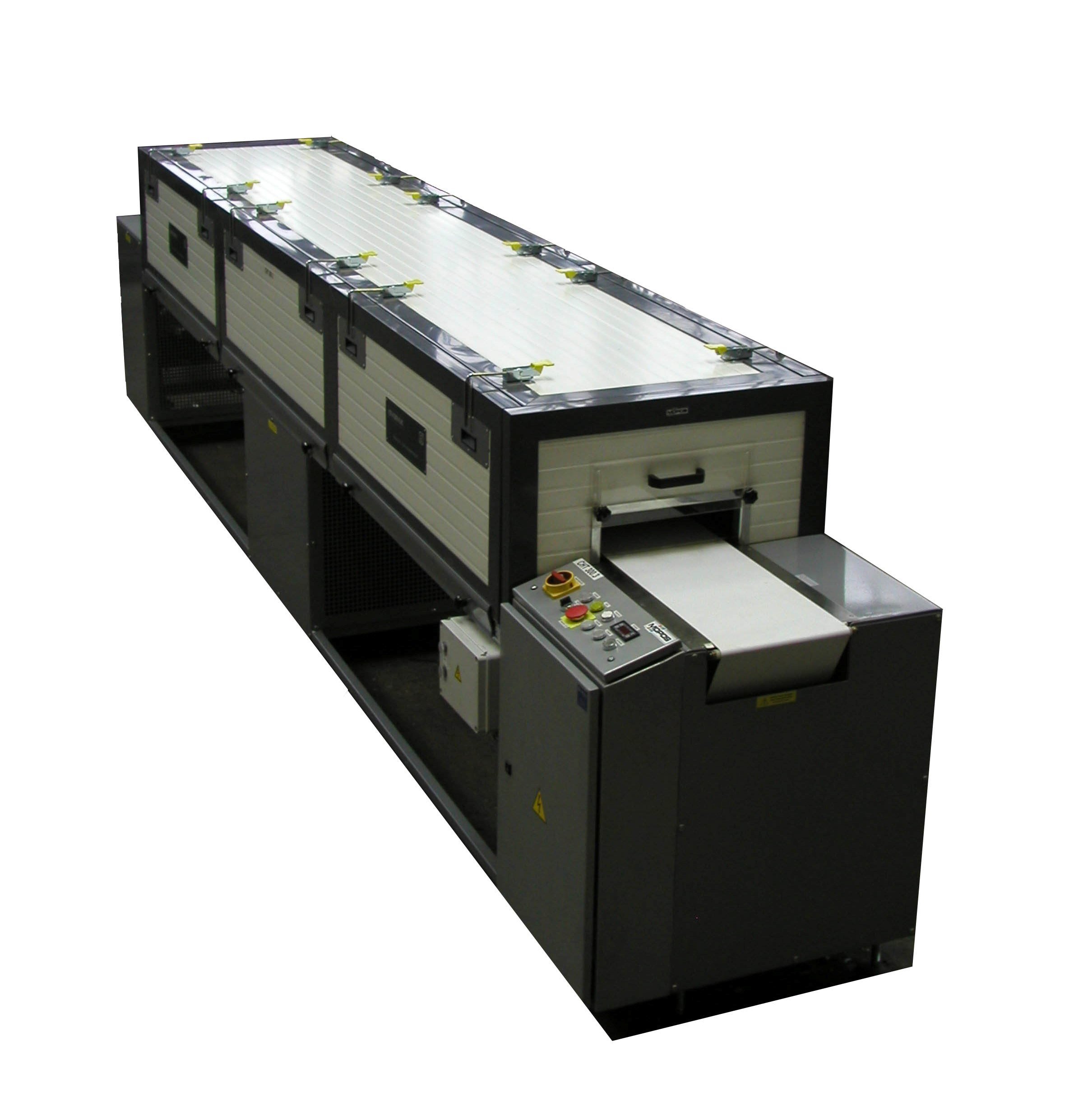

Cooling tunnel CHT 300/600

The CHT cooling tunnels are produced in two basic modifications CHT 300 and CHT 600 with different belt width.

The cooling tunnels are supplied with cooling units of different capacities dependent upon the actual refrigerating output and the length of the tunnel. These cooling units may be located in the midsection of the tunnel , on its outside or even outside the building – as per customer’s requirements. The coolant used is environment-friendly liquid.

Cooling tunnels are manufactured in various lengths depending upon the kind of the cooled product and the space accessible for the installation.

The machine is standardly equipped with the PVC conveyer belt in two widths: 300 and 600 mm. However, a belt of any size may be supplied in accordance with the customers’ demands.

The outer casing and insulation provides maximum efficiency of the CH cooling tunnels as well as minimum energetic requirements.

The equipment utilizes modern technical elements, has automatic tightening and alignment of the belt, refrigerating compressor and cooling unit. Everything is build in a single compact form including the control panel.

Parametres

-

Length mmCHT 300

5000CHT 600

6000 -

Width mmCHT 300

800CHT 600

1000 -

Height mmCHT 300

1300CHT 600

1400 -

Belt width mmCHT 300

300CHT 600

600 -

Length of cooling space mmCHT 300

300CHT 600

600 -

Belt speed mmCHT 300

0,3 - 1,8CHT 600

0,3 - 1,8 -

Maximum product height mmCHT 300

0,3 - 1,8CHT 600

600 -

Input mmCHT 300

4,5CHT 600

6 -

Voltage system V/Hz

CHT 300

3NPE 400/230/50CHT 600

3PNE 400/230/50