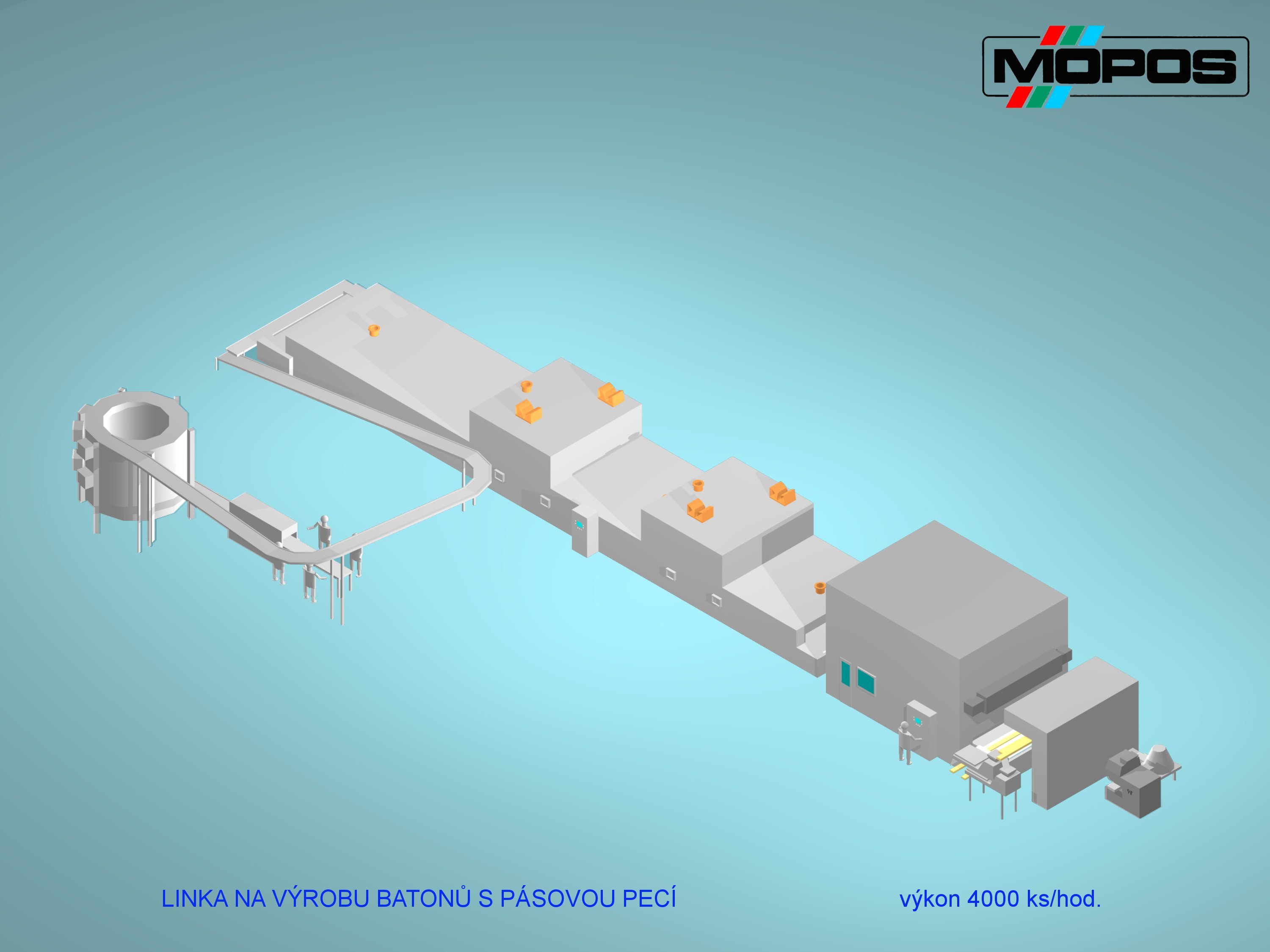

This production line is designed for wheat baguettes or batons of weight range 250 - 450g and wheat buns of 200 g and designated primarily for Eastern markets. The line is supplied in different modifications depending on specific requirements of the customers and their plant layout.

The whole production process from intermediate proofing, moulding, fitting, proofing, notching, moistening to baking is fully automated.

Lines are supplied for capacities ranging from 800 to 4,200 pcs/hr. Only one person is needed to operate the whole line.

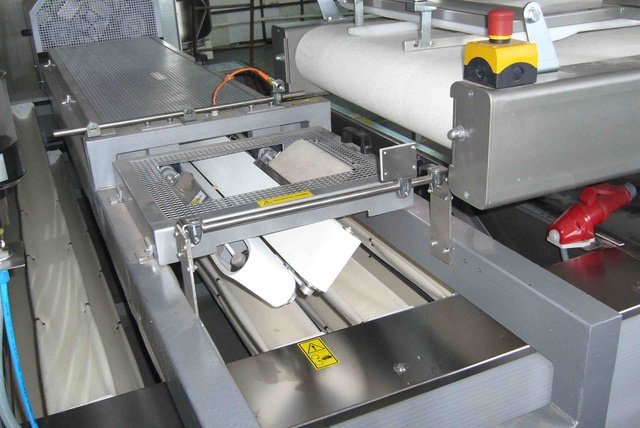

Moulding equipment for the line comprises of high-quality machines produced by Sweden based company Glimek. These guarantee first-class, stress-free dough moulding and faultless operation.

Proofers for lines with capacities exceeding 2,500 pcs/hr are loaded from both sides and moulding equipment is therefore doubled